The Role of 3d Printing in the Future of Tire Molds for Retreading

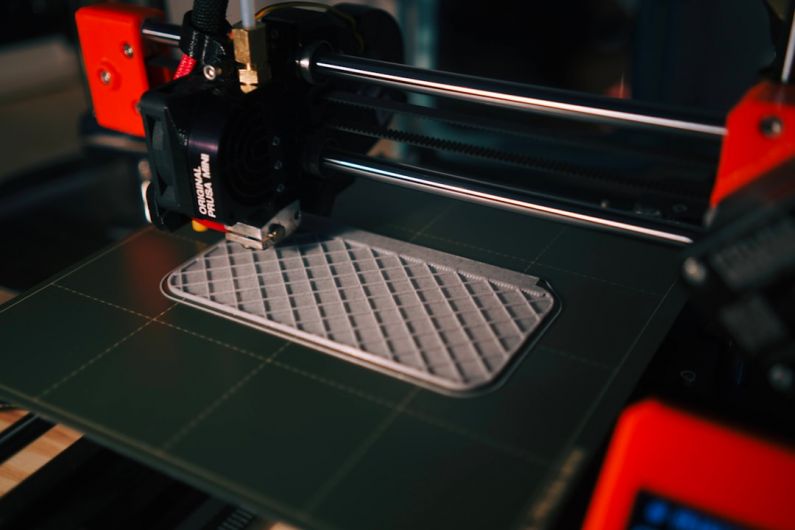

Innovations in technology have revolutionized various industries, with 3D printing emerging as a game-changer in the manufacturing sector. One area where 3D printing is making significant strides is in the production of tire molds for retreading. As the demand for sustainable and cost-effective solutions continues to rise, the role of 3D printing in the future of tire molds for retreading is becoming increasingly prominent.

Advantages of 3D Printing in Tire Mold Production

Traditional methods of manufacturing tire molds can be time-consuming and costly. However, 3D printing offers a more efficient and cost-effective alternative. By using 3D printing technology, manufacturers can create intricate and customized tire molds with minimal waste. This process not only reduces production time but also allows for greater design flexibility, resulting in improved tire performance.

Improved Design Capabilities

One of the key advantages of 3D printing in tire mold production is the ability to create complex and precise designs. Traditional manufacturing methods often have limitations when it comes to intricate mold designs. With 3D printing, manufacturers can produce molds with intricate patterns and textures that were previously unattainable. This level of design flexibility enables tire manufacturers to create molds that are tailored to specific performance requirements, resulting in enhanced tire quality and durability.

Cost-Effective Production

In addition to offering design flexibility, 3D printing also provides a cost-effective solution for tire mold production. Traditional manufacturing methods require expensive tooling and equipment, making them less viable for small-scale production. 3D printing eliminates the need for costly tooling, allowing manufacturers to produce molds on-demand and in small quantities. This not only reduces production costs but also minimizes waste, making 3D printing a more sustainable option for tire mold production.

Enhanced Performance and Durability

The precision and accuracy of 3D printing technology result in tire molds that offer superior performance and durability. By using 3D printing to create molds, manufacturers can ensure consistent and uniform tire tread patterns, leading to improved traction and handling. Additionally, the durability of 3D-printed molds allows for longer mold lifespans, reducing the need for frequent replacements and maintenance.

Environmental Sustainability

As the global push for sustainability continues to grow, the role of 3D printing in tire mold production is becoming increasingly important. Traditional manufacturing methods often generate a significant amount of waste, both in terms of materials and energy. 3D printing, on the other hand, is a more environmentally friendly option, as it produces minimal waste and consumes less energy during the production process. By adopting 3D printing technology for tire mold production, manufacturers can reduce their environmental impact and contribute to a more sustainable future.

Future Outlook

The future of tire mold production is undoubtedly being shaped by advancements in 3D printing technology. As the capabilities of 3D printing continue to evolve, we can expect to see even more innovative designs and materials being used in tire mold production. With its cost-effective, sustainable, and customizable features, 3D printing is set to revolutionize the way tire molds are manufactured, paving the way for more efficient and high-performing tires in the future.

In conclusion, the role of 3D printing in the future of tire molds for retreading is poised to bring about significant improvements in design flexibility, cost-effectiveness, performance, and environmental sustainability. By harnessing the power of 3D printing technology, tire manufacturers can create molds that are not only superior in quality but also contribute to a more sustainable and efficient manufacturing process.